LIFT PARK

The LIFT

PARK is an automated pallet parking system. The vehicles parked on pallets

are transported:

» vertically - by

a central lift with the pallet extractor,

» horizontally - on

roller tracks.

Next to the LIFT PARK entrance, there is the enter-and-exit terminal with control system and complementary accessories according to the client’s choice.

The powerful industrial computer enables fully automatic operation and the system transports the vehicle to the client in the fastest and shortest way. A client can order a vehicle turntable to enter and exit easily.

The LIFT PARK system can operate in underground garages or in multi-level buildings. We offer the three options of the system with different depth of the lift. Each size can be in different combination of the vehicle heights: 170 and 190 centimeters and vehicle length up to 540 centimeters and the vehicle width of 230 centimeters. Weight capacity of the vehicle is up to 3000 kilograms.

Each

pallet has a drain for vehicle’s water and oil leakage.

The LIFT PARK can be used in large-capacity garages combining different individual systems (versions A, B, C) in order to access a stored vehicle in the fastest possible way.

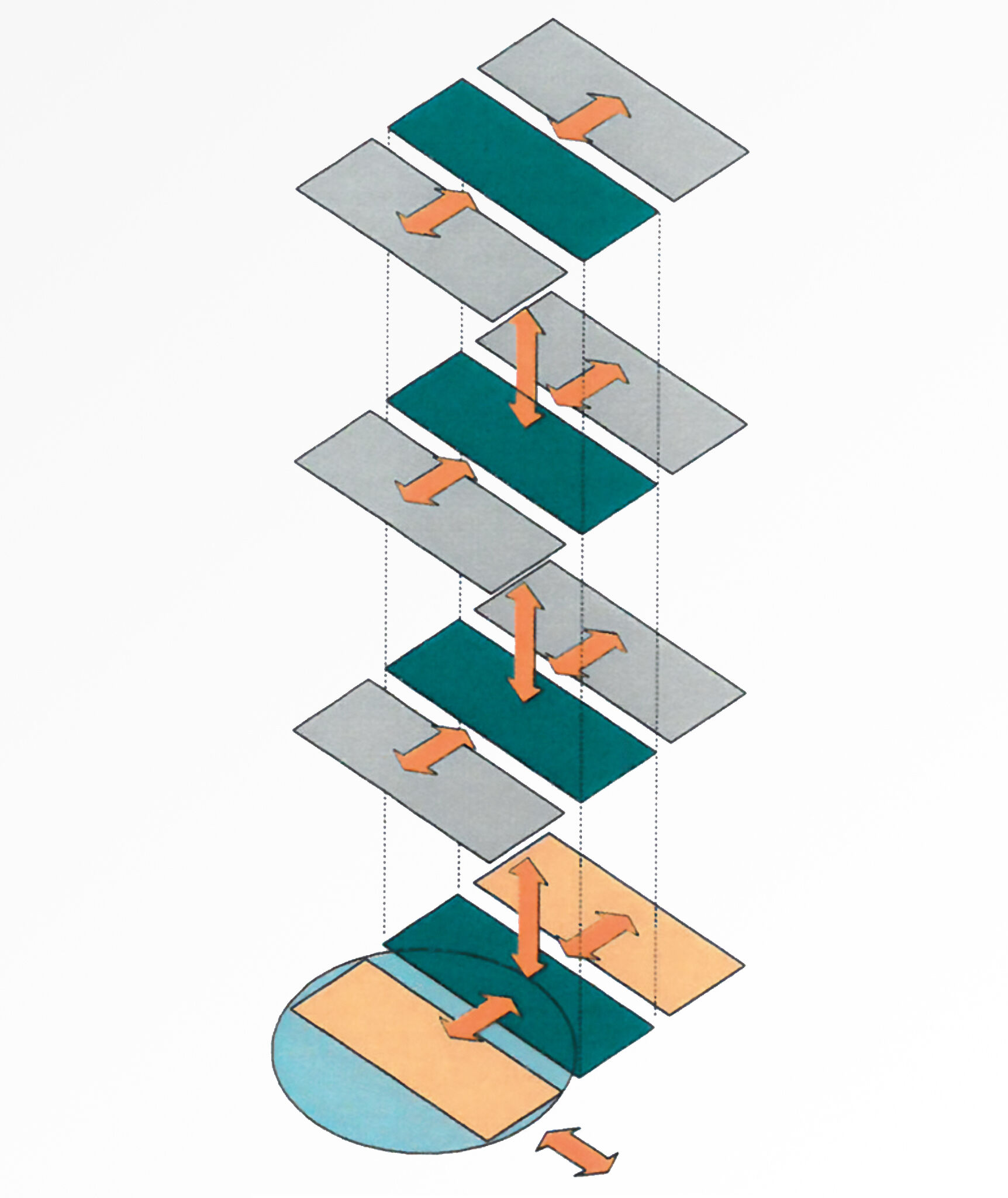

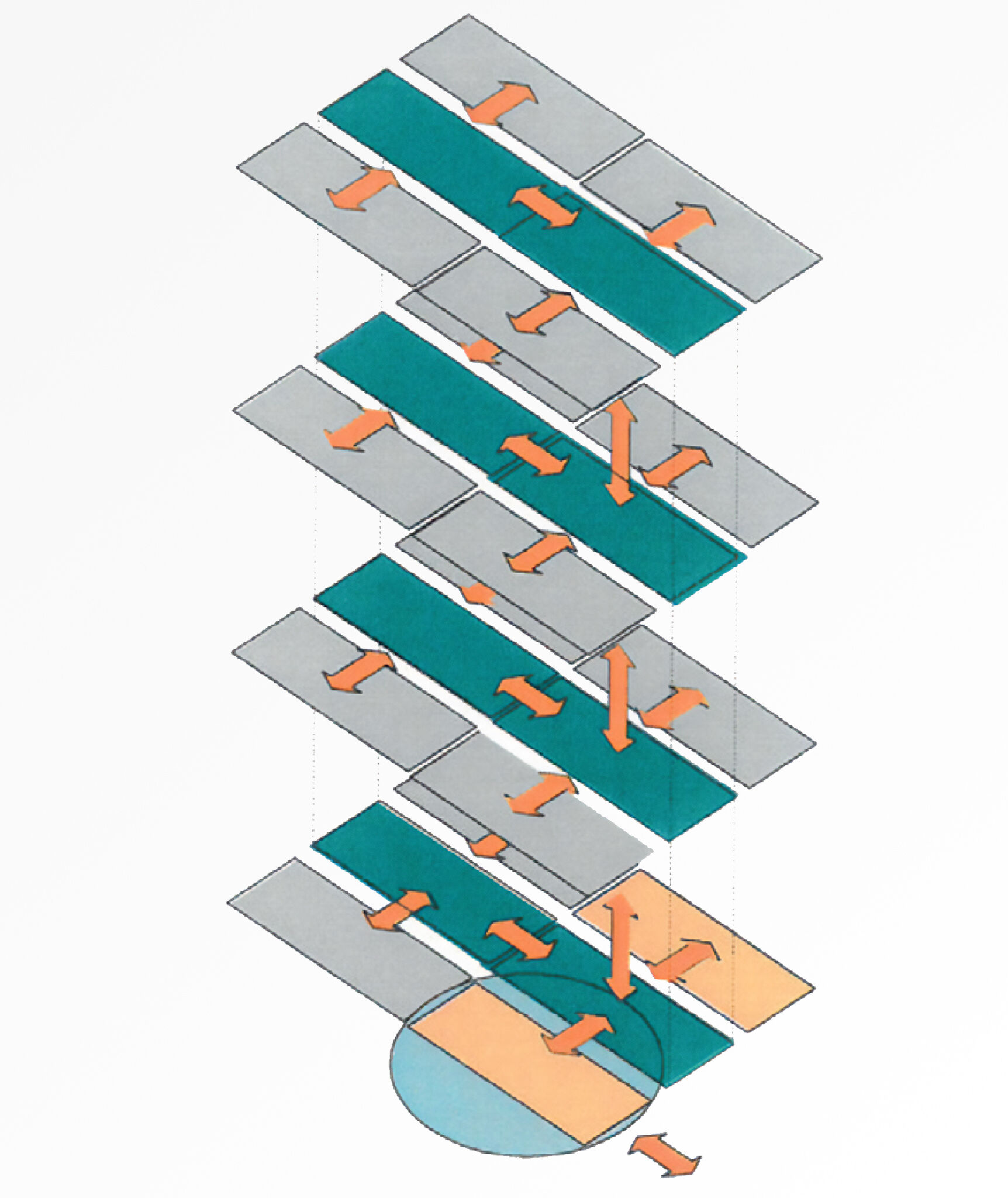

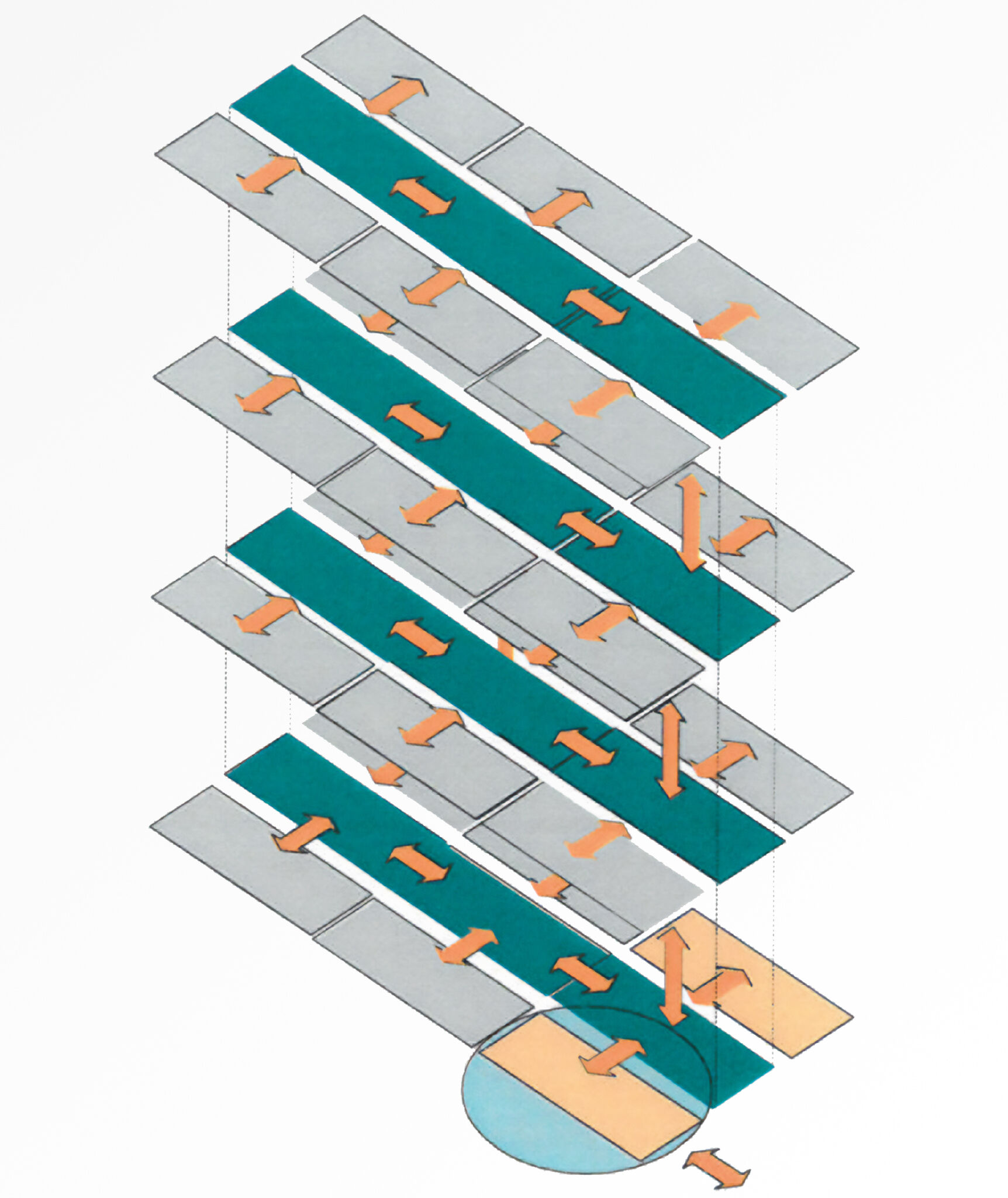

The LIFT PARK system comes in different versions varying in lift types and in number of levels of vehicle storage places in a row.

VARIANTS OF SYSTEM:

» Type A: It is the easiest mono version of the LIFT PARK. It consists of one level of the vehicle storage places and simple lift with the extractor which operates one vehicle pallet at a time. In the process of parking a vehicle, the extractor moves the vehicle pallet from the entrance terminal to the lift. Then the pallet transfers the vehicle on the floor with an empty storage place on which the pallet is ejected. When the client retrieves the vehicle from the LIFT PARK, the process is in the reverse order.

» Type B: It is a duo version of the LIFT PARK. It consists of two levels of the vehicle storage places in a row. The system includes double lift with the horizontal sliding extractor which operates one vehicle pallet at a time. In the process of parking a vehicle, the extractor moves the vehicle pallet from the entrance terminal to the lift. Then the pallet transfers the vehicle on the floor with an empty storage place on which the pallet is placed. Unlike the type A, the type B extractor provides two positions in the lift: front and rear, and so it can operate both levels. When the client retrieves the vehicle from the LIFT PARK, the process is in the reverse order.

» Type C: It is a trio version of the LIFT PARK. It consists of three levels of the vehicle storage places in a row. The system includes triple lift with the horizontal sliding extractor which operates one vehicle pallet at a time. In the process of parking a vehicle, the extractor moves the vehicle pallet from the entrance terminal to the lift. Then the pallet transfers the vehicle on the floor with an empty storage place on which the pallet is placed. Unlike the type A, the type C extractor provides three positions in the lift: front, middle and rear, and so it can operate all three levels. When the client retrieves the vehicle from the LIFT PARK, the process is in the reverse order.

THE ADVANTAGES OF THE LIFT PARK SYSTEM:

» the

optimal solution for high-capacity systems;

» constructing

in underground garages or in multi-level buildings;

» an

individual project for every location;

» the

possibility of smaller modules built within bigger systems;

» the

ability to park with minimal walking distance;

» quick

access to stored vehicles.